- Joined

- Sep 29, 2024

- Messages

- 92

Recently I had posted on my suspension post about an issue with rear wheel hub bearings. I said I would post about the improvement upgrade as I was stepping through it. This is the beginning of that upgrade.

One of the other issues with the factory rear design are the bolt heads & fit. The compression part of the bolt head, the diameter, is to small & the fit of the bolt shank is far to small. The diameter of the through hole in the brake backing plate is .395 to .400, but the through hole in the hub bearing is .460! With the bolt size being 10mm (.390.), the more important fit is the bolt size to the hub bearing! So the whole setup is garbage! The clearance fit of the bolt to the hub bearing should be no more than .015 total, .0075 on a side, with .010 total or .005 on a side being ideal.

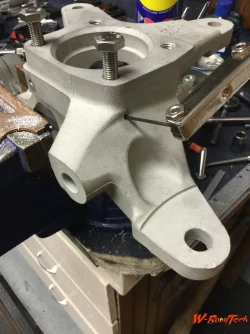

So here is the start of this improvement modification. My advice would be get a spare set of knuckles. So obviously I would recommend sandblasting or glass bead the knuckles if they’re not new.

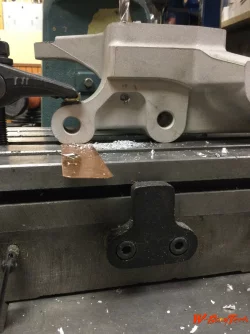

Now drill the two 10mm threaded holes that are on the opposite side from the caliper mounting flange of the knuckle deeper, about 2.250” deep total. These two holes are blind. The setup to do this should be done on a mill as you will see in the attached pictures.

Now you will flip the knuckle over to spot face the backside of the two short 10mm through holes. This is done to make a flat surface for the new bolt arrangement that will be used. This arrangement will change the two through holes from 10mm x 1.5mm to 7/16 14 thread. This is done by drilling those two holes out to the tap drill size of a 7/16 x 14 bolt. Then tap the hole with a 7/16 tap. You will notice that drilling out the 10mm taped holes does not remove all the threads. That’s ok! Metric threads are a very different animal when compared to US threads! American threads are far & away superior to metric, fact based from the principles of what threads are! I don’t just say that because I’m American. Metic threads are weaker, strip more often & in general defy the good principles of threading, which is considered an art form! And has been from almost the beginning. I can speak to this later if someone wants to know more, but for now you’ll never know that there was ever a 10mm thread there when finished!

Next you will need to open up the two holes on the brake backing plate that corresponds to the 7/16 bolts. Drill them out to 7/16.

One of the other issues with the factory rear design are the bolt heads & fit. The compression part of the bolt head, the diameter, is to small & the fit of the bolt shank is far to small. The diameter of the through hole in the brake backing plate is .395 to .400, but the through hole in the hub bearing is .460! With the bolt size being 10mm (.390.), the more important fit is the bolt size to the hub bearing! So the whole setup is garbage! The clearance fit of the bolt to the hub bearing should be no more than .015 total, .0075 on a side, with .010 total or .005 on a side being ideal.

So here is the start of this improvement modification. My advice would be get a spare set of knuckles. So obviously I would recommend sandblasting or glass bead the knuckles if they’re not new.

Now drill the two 10mm threaded holes that are on the opposite side from the caliper mounting flange of the knuckle deeper, about 2.250” deep total. These two holes are blind. The setup to do this should be done on a mill as you will see in the attached pictures.

Now you will flip the knuckle over to spot face the backside of the two short 10mm through holes. This is done to make a flat surface for the new bolt arrangement that will be used. This arrangement will change the two through holes from 10mm x 1.5mm to 7/16 14 thread. This is done by drilling those two holes out to the tap drill size of a 7/16 x 14 bolt. Then tap the hole with a 7/16 tap. You will notice that drilling out the 10mm taped holes does not remove all the threads. That’s ok! Metric threads are a very different animal when compared to US threads! American threads are far & away superior to metric, fact based from the principles of what threads are! I don’t just say that because I’m American. Metic threads are weaker, strip more often & in general defy the good principles of threading, which is considered an art form! And has been from almost the beginning. I can speak to this later if someone wants to know more, but for now you’ll never know that there was ever a 10mm thread there when finished!

Next you will need to open up the two holes on the brake backing plate that corresponds to the 7/16 bolts. Drill them out to 7/16.

Attachments

-

A744C4C9-CCF7-49D5-AA4B-3A9162FF9F6D.webp264.6 KB · Views: 97

A744C4C9-CCF7-49D5-AA4B-3A9162FF9F6D.webp264.6 KB · Views: 97 -

EEEFCF44-D4A9-4DDA-974D-4A6F8B097060.webp295.6 KB · Views: 94

EEEFCF44-D4A9-4DDA-974D-4A6F8B097060.webp295.6 KB · Views: 94 -

C4DC971C-8740-4223-9124-04E7177C92C6.webp279.2 KB · Views: 90

C4DC971C-8740-4223-9124-04E7177C92C6.webp279.2 KB · Views: 90 -

DBEC6DF7-5FED-4926-B3F6-843D4BE71841.webp316.1 KB · Views: 95

DBEC6DF7-5FED-4926-B3F6-843D4BE71841.webp316.1 KB · Views: 95 -

9AB6603B-75C4-462F-999B-0B2D4C8019DF.webp359.2 KB · Views: 94

9AB6603B-75C4-462F-999B-0B2D4C8019DF.webp359.2 KB · Views: 94 -

32980DA4-A8BC-43AF-A403-A87A13307442.webp307.1 KB · Views: 84

32980DA4-A8BC-43AF-A403-A87A13307442.webp307.1 KB · Views: 84 -

1208BF1D-B5DD-41D3-8D07-3E6E049A2C40.webp388.3 KB · Views: 89

1208BF1D-B5DD-41D3-8D07-3E6E049A2C40.webp388.3 KB · Views: 89 -

823C819D-AB79-4017-9CD9-02247BCC8DD8.webp252.1 KB · Views: 84

823C819D-AB79-4017-9CD9-02247BCC8DD8.webp252.1 KB · Views: 84 -

0FCDC70D-7DF1-4235-8389-91BD953B2EAA.webp242.2 KB · Views: 93

0FCDC70D-7DF1-4235-8389-91BD953B2EAA.webp242.2 KB · Views: 93 -

2CDA430E-9F21-4D2F-A419-65215C5A9A3E.webp244.6 KB · Views: 97

2CDA430E-9F21-4D2F-A419-65215C5A9A3E.webp244.6 KB · Views: 97