Speaking of the suspension, I would offer this cautionary story if you plan to build a ground pounder as they are called! I can not speak about all FWD’s as I have not built the suspensions of all manufacturers, but of all GM & the like there is a serious issue with McPherson strut/knuckle suspension vehicles, especially when it comes to building an aggressive handling suspension. This is due to the illogical application of the wheel bearing design!

In a traditional rear wheel drive the bearings are installed on a traditional spindle with two tapered roller bearings. This design can not fail, I.E. the wheel falls off! Other than to have a bearing go bad, there is little else to occur beyond stranded! As it would be virtually impossible, due to bearing failure, for the wheel to come off!

That is not the case with a FWD! The rear hub bearings are held in place by bolts that thread into the knuckle. Which pushes the wheel hub into the knuckle. The wheel obviously bolts to the hub. If the hub bolts that are threaded into the knuckle fail for any reason, the hub has nothing to keep it in the knuckle, or the wheel on the car!

This was such the case for me! Fortunately I caught my problem before it became a dilemma or catastrophe. When I built this suspension many years ago I built everything new from the ground up, including hub bearings. They were done more than correctly! The fit to the knuckle was a little tighter than factory & the torque was 5 pounds more. And yes it has taken nearly 20 years to raise its head, but that’s only about 15,000 miles.

So it went like this. For the last half of last summer & most of this past summer every time I would make a hard, I.E. aggressive right turn I would get this rattling noise from the left rear that kind of sounded like decelerating exhaust while in the cornering sequence. Straight forward driving it seemed quiet. Over & over again I would check & recheck, exhaust, brakes, tire rub, suspension clearance, suspension component torque, etc., but nothing! It drove me nuts, because I knew something was wrong. I took out the back seat pulled the access plate to the fuel pump. Now it appeared more metallic then. Took it on the freeway & now I would hear a intermittent hard metallic crack. That was it, I knew I needed to put it up in the air & go through the whole back suspension piece by piece, oh great!

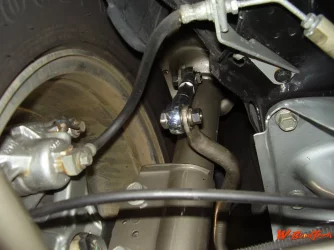

Well I didn’t have to go far. Removed left wheel, caliper, rotor & bingo! There it was! Looking through the access holes of the bearing hub tire mounting flange was a hub mounting bolt. Loose & bent. I replaced it & checked the torque on the other 3 bolts. All were loose! I check the other side. One needed re-torque slightly, the rest were good.

My take on this is this. The hub bearing mounting setup is poor at best, but the front is better than the back. The front use 3 larger bolts mounted from the back. This is better because in hard cornering, the loaded wheel, this places the bolts in compression & the bearing receives more of a angular vertical load. So while this is far less than optimal, it’s by far better than the back.

On the other hand the back is abysmal! In a hard corner the rear load wheel has a similar load as the front, but the bolts are a third of the diameter & they’re being stretched & the following wheel is also being stretched because they hold the bearing hub from the front.

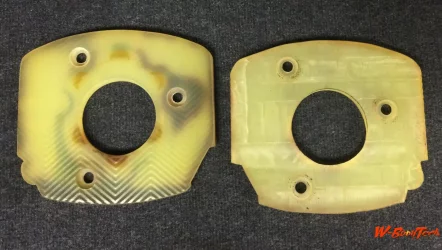

I have a new design for these that I will build this winter. As I do I will share it with you folks so if you chose you’ll be able to incorporate it as well. This design will be more in the vain the a spindle type attachment that will have a means to be a fail safe design that would prevent this type of bolt failure.